Tork Coreless Midsize Advanced 2p 900s (36)

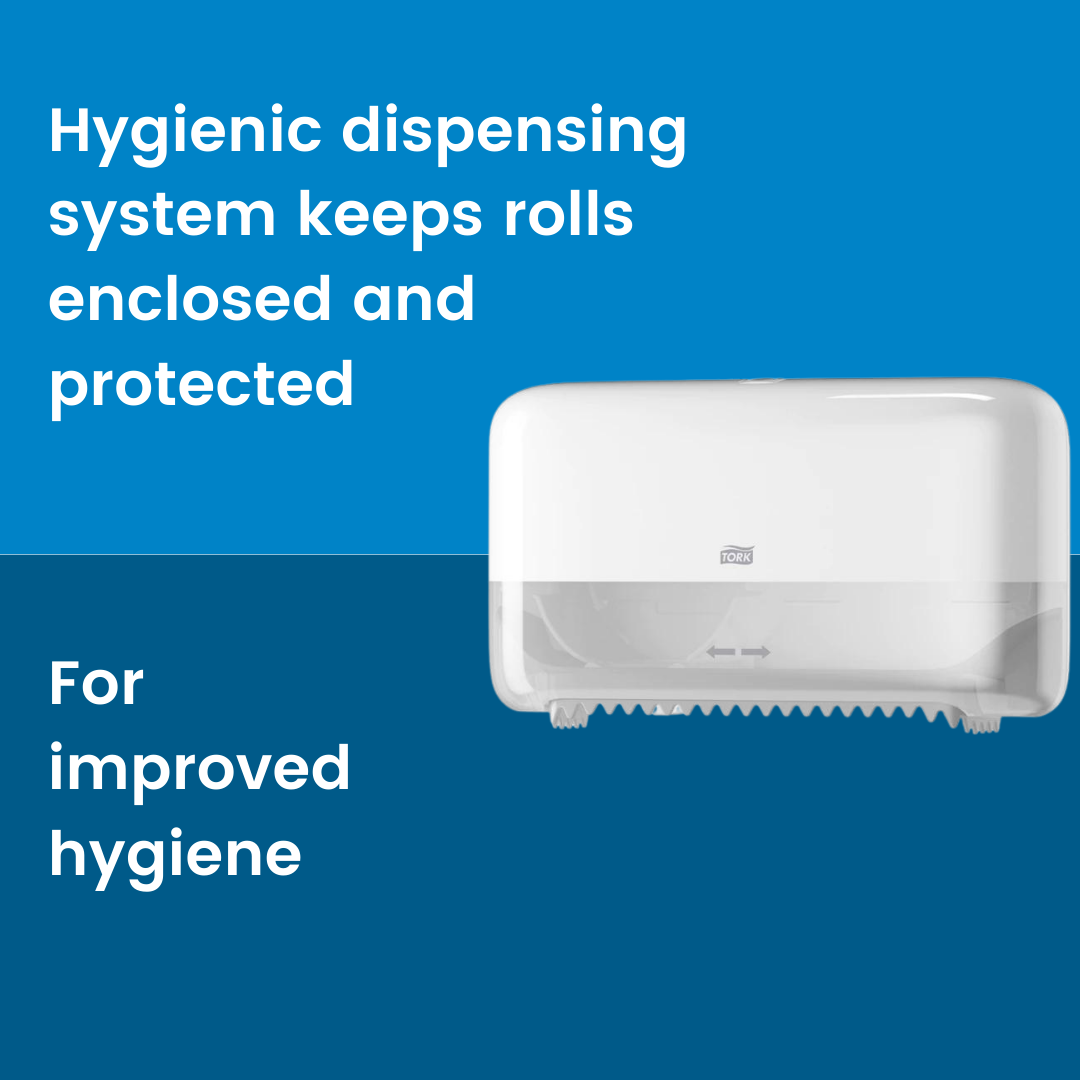

The Tork Twin Coreless Mid-size Toilet Roll Dispenser system is ideal for low to medium traffic washrooms with a high focus on guest satisfaction.

Free On Loan Dispenser*

*Terms and conditions apply.

€99.28

Shipping 1-2 Business Days

Trading for over 25 Years

It ensures high efficiency and that toilet paper is always available for guests by holding two full mid-size rolls. The Advanced Tork Coreless Mid-size Toilet Roll balances cost and performance.

- Coreless rolls produce no waste

- Compact mid-sized rolls: Each equivalent to 4-5 conventional toilet rolls

- Attractive d?cor: designed to make a great impression

Key Features

System T7 – Midsize Coreless System

Roll length 103.5 m

Roll width 9.3 cm

Roll Diameter 13.1 cm

Number of Sheets 900

Sheet legth 11.5 cm

Ply 2

Print No

Embossing Yes

Colour White

Recycled fibres

The packaging material is made from paper or plastic.

Material

Virgin fibres and recovered paperIn the tissue process both virgin fibres and recovered paper are being used. The choice of pulp is made based on product requirements and pulp availability so the pulp is used in the most efficient way.The environmental benefits and economic feasibility of recovered paper as a raw material source depend on its availability, transport distance and the quality of the collected material. Recycling of paper is an efficient use of resources as the wood fibres are used more than once.High demands are put on quality and purity of recovered fibres, considering each step of the chain (collection, sorting, transportation, storage, use), to ensure safe and hygienic products.Recovered paper can be produced both from collected newsprint, magazines and office waste. The choice of recovered paper grades, is made for each product, depending on its specific requirements on performance properties and brightness. The paper is dissolved in water, washed and treated with chemicals under high temperature and screened to separate out impurities.Virgin pulp fibres are produced out of softwood or hardwood. The wood is subject to chemical and/or mechanical processes where the cellulose fibres are separated out and lignin and other residuals are removed.Bleaching is a cleaning process of the fibres and the aim is to achieve a bright pulp, but also to get a certain purity of the fibre in order to achieve the demands for hygiene products and in some cases to meet the requirements for food safety.There are different methods used today for bleaching: ECF (elementary chlorine free, where chlorine dioxide is used, and TCF (totally chlorine free) where ozone, oxygen and hydrogen peroxide is used.Bleaching of the recovered pulp is made with chlorine-free bleaching agents (hydrogene peroxide and sodium dithionite).Chemicals

All chemicals (process aids as well as additives) are assessed from an environmental, occupational health and safety and product safety point of view.To control product performance we use additives:

- Wet strength agents (for Wipers and Hand Towels)

- Dry strength agents (are used together with mechanical treatment of the pulp to make strong products like wipers)

- For coloured papers dyes and fixatives (to secure perfect fastness of the colour) are added

- For printed products printing inks (pigments with carriers and fixatives) are applied

- For multi ply products we often use a water soluble glue to secure the integrity of the product

In most of our mills we do not add optical brighteners but it often occurs in recovered paper since it is used in printing paper.We do not use softeners for professional hygiene products.High product quality is secured through quality and hygiene management systems throughout production, storage and transport.In order to maintain a stable process and product quality the paper manufacturing process is supported by the following chemicals/ process aids:

- defoamers (surfactants and dispersing agents)

- pH-control (sodium hydroxide and sulphuric acid)

- retention aids (chemicals that help to agglomerate small fibres to prevent fibre loss)

- Coating chemicals (that help to control the creping of the paper to make it soft and absorbent)

To reuse broke and to utilise recovered fibres we use:

- Pulping aid (chemicals that help to repulp wet strong paper)

- Flocculation chemicals (that help to clean out printing inks and fillers from recovered paper)

- Bleaching agents (to increase the brightness of pulp from recovered paper)

In the cleaning of our waste water we use flocculation agents and nutritients for the biological treatment to secure that no negative impact on?water quality comes from our mills.Environmental certificationThis product is certified with the EU Ecolabel with certificate number SE/004/001.This product is certified for FSC? with certificate number SA-COC-008266.Packaging

Fulfilment of Packaging and Packaging Waste Directive (94/62/EC): Yes

- Hibernia Medical does not supply goods on a sale or return basis.

- Hibernia Medical does not accept the return of goods without prior written communication to the Customer Service department.

- Goods can be returned once approval in writing has been given by Hibernia Medical.

- A ‘Goods Return Form’ must be completed for all returns. Notification of the intent to return Goods must be made within 14 days of the Delivery/Invoice date.

- The only goods that will accepted for refund must be a current stock line and not a discontinued line, nonreturnable product or a special-order item.

- All approved goods for return must be in perfect condition, in original packaging, sellable and be completely without defect or damage. Such damage will totally cancel any obligation by Hibernia Medical for any refund whatsoever on the item.

- Electrical and photographic equipment will only be accepted if complete with all leads, accessories and software. Any software must have its original seal intact.

- Goods are returned at the sender’s responsibility and cost. Hibernia Medical accepts no responsibility for goods lost or damaged during return transit. We recommend that the returned item(s) to our office are registered/tracked. Additionally, Hibernia Medical does not refund return carriage, postage fees or insurance costs.

- Please check the package and label before opening any products to ensure that you have received the correct items. Shipment errors must be reported no later than seven (7) days after the invoice date.

- Non-stock items and special-order items are subject to a no-return policy.

- All sales of clearance items are final and we cannot accept returns.

Please Note: Special order items and discontinued items are not subject to this returns policy and will be dealt with on a case-by-case basis.

All items returned are subject to a restocking fee of 10%.

Items returned after 14 days are liable to additional handling charges:

- 14 – 21 days old 15% of invoice value or minimum of €20.00

- 21 – 30 days old 20% of invoice value or minimum of €20.00

- 31 – 60 days old 25% of invoice value or minimum of €20.00

- Returns after 60 days are dealt with on a case-by-case basis

If you return part or all of your order, we will not refund the delivery charge as this part of our service to you has been completed. In the cases of incorrect, damaged or faulty goods, the delivery charge for a replacement to be sent out will not be charged.

For returns/refunds requests within 14 days please contact our Customer Service Team on 01 8665727 or email [email protected]

If you’ve asked for a refund, we will credit the account you used to pay for your order. Please allow up to 14 days for the refund to appear on your account.

Our Address:

Hibernia Medical

E3 Calmount Business Park

Ballymount

Dublin 12

D12 NA40

You May Also Like

Bosch

Littmann

Saver One

Omron

Omron

Iem

Braun

and

riester

mesi

medi Plent

sono site

wench allyn

plinth medical